As we walked up to the DIAMANTE process factory, it DID look like something out of star wars. Tall silos contained untreated and treated cork flour, a huge compressed CO2 cylinder, compressors, pipes, coolant lines, electrical, and lots of other equipment that was difficult to totally understand.

Oeno has several patents on the process and equipment used in their TCA extraction process. The entire process is very complex, and uses many, many steps, but to simplify: They use supercritical CO2, which is CO2 at high pressure and moderately high temperature - this gives it some of the properties of a liquid and some of the properties of a gas. As such, it has huge ability to penetrate the cork granules to extract volatiles, and is very effective as a solvent to remove these contaminants. At the same time, it is relatively gentle on the structure of the cork itself, and does not cause physical deformation of the suberin. Nearly all of the CO2 used is run through an activated carbon filter to remove the TCA and other contaminants, and then it can be reused within the cycle again. CO2 is completely non-toxic, and is a byproduct of many other industries (even winemaking!) so this is considered an extremely 'green' method of extraction, and is now used in applications ranging from decaffeinating coffee to dry-cleaning clothing!

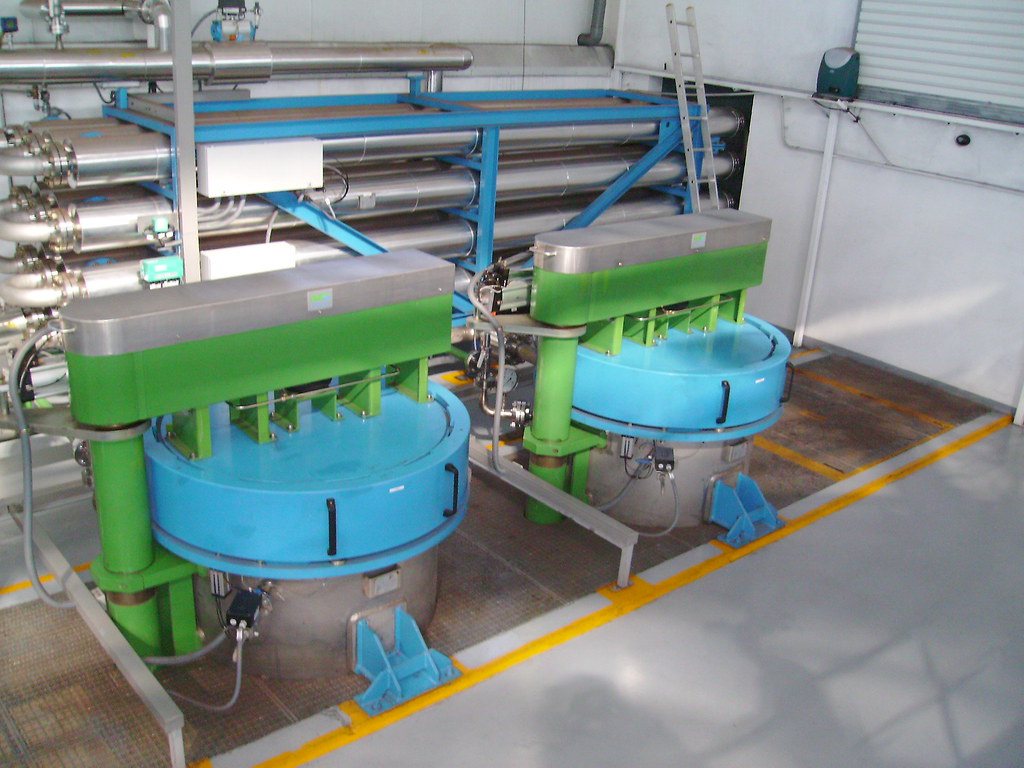

The actual treatment occurs in several tall cylinders, in a batch process. Dominic showed us their very first, prototype extractor, which was in a bay all by itself. "This is the only French-made machine in the entire plant. We have Italian machines, lots of German machines, some Japanese machines, but this is the only French, and now it is not used anymore." (I asked him if, as it was a French machine, it had decided to go on strike!)

We went outside to see where the TCA was collected, along with about 150 other compounds that they had identified so far, in a plastic chemical tote. We smelled it; it smelled vaguely corky, like sawdust and a little woody, but not overwhelmingly like TCA. They are collecting about 300 gallons of this stuff per week - it is completely non-toxic, and they have been discussing the possibility of selling it to some perfume companies, as several of the recoverable compounds are difficult to obtain, and are valuable in perfumery.

From here, the now-treated cork flour travels over to another plant where it is formed, mixed, and turned into closures.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment